AP Precision: Your Partner in Scalable, High‑Quality Metal Fabrication

Integrated Manufacturing That Scales with Your Growth

At AP Precision, our mission is clear: provide seamless, scalable manufacturing solutions for annual volumes ranging from 100 to 10,000 EAU, all within our 40,000 sq ft facility in San Diego, CA. Whether you’re launching a new product line or managing peak production periods, our automated yet flexible systems enable quick ramp‑ups and cut‑in revisions—without additional tooling costs—ensuring you stay competitive in price and delivery speed.

Advanced Cutting & Laser Technology

Investment in industry‑leading fiber lasers—spanning 4 kW, 10 kW, and 12 kW platforms—allows us to process a broad range of alloys and thicknesses (20 GA to 1.5″ plate). Our cutting precision exceeds ±0.001″, and with over 300,000 lb of metal processed monthly, we handle both high‑volume flat parts and complex multi‑step components.

Flexible Forming & Precision Bending

From manual press brakes for low‑volume runs to automated cells for higher annual volumes, our forming capabilities are designed for efficiency and adaptability. We expertly handle intricate bends and complex geometries—without the high cost of stamped tooling.

Cutting‑Edge Welding Solutions

Our welding department includes both robotic and manual cells, with hybrid setups for specialized runs. Supported by certified AWS welders, we deliver reliable, cost‑effective fabrication with rapid ramp‑up for new products.

Maintaining an in‑house powder coat line and adding Linex polyurea finishes in 2022 lets us fully control coating quality, timing, and cost :contentReference[oaicite:5]{index=5}. We also offer stainless passivation up to 64″×42″×26″ (ASTM A967), plus trusted partners for anodizing, plating, silkscreen, laser etching, and more.

Beyond fabrication, AP Precision excels at assembly, heavy‑handling, kitting, and labeling. By integrating early stages of your product build, your team can focus on electrical assembly and functional testing. Final products arrive packaged and ready for shipment.

We intentionally operate at ~30% capacity to provide rapid response for prototypes, spikes, and special orders. With on‑site storage, Kanban inventory systems, and full in‑house production control (ISO 9001:2015), we ensure tight lead‑time reliability, cost‑efficiency, and consistent quality.

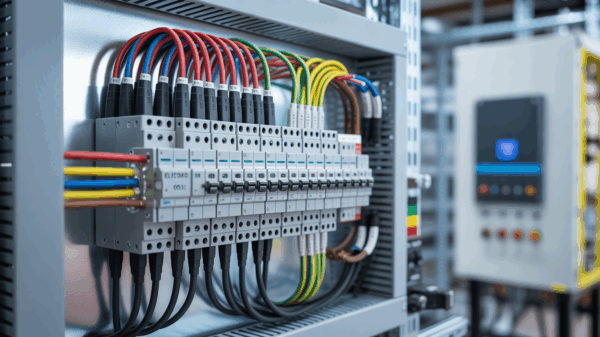

AP Precision is nationally recognized for aluminum busbar fabrication—offering excellent conductivity at lower cost and weight compared to copper. Our capabilities include cutting and bending profiles from 0.063″ to 0.500″ thick and up to 18″ wide, optimized for modern electrical systems.

With state‑of‑the‑art bending machines, hydraulic precision controls, and cold spray techniques, we maintain mechanical integrity while enabling complex, reliable busbar designs.

Aluminum’s lower cost, lighter weight, corrosion resistance, and recyclability make it an attractive alternative to copper—without sacrificing performance when designed properly. And with advanced manufacturing, it meets and often surpasses industry standards.

Our dedicated Quality Control team ensures reliable delivery and traceability. We’ve maintained ISO 9001 compliance since 2011 and achieved ISO 9001:2015 certification in fall 2022. This rigorous process includes systematic root‑cause analysis and continuous improvement—safeguarding your product integrity.

Located in San Diego, we remain committed to domestic manufacturing. Unlike competitors who offshore work, we support local employment, source American materials, and offer consistent quality without overseas logistics complexity. Zero employee turnover and profit‑sharing keep our team dedicated and accountable.

Across these sectors, we track project specifics from concept through packaging—covering fabrication, welding, finishing, assembly, and endpoint delivery.

Choosing AP Precision means partnering with a long‑term ally. You gain access to:Industry‑Leading Finishing & Coatings

Assembly, Kitting & OEM Support

Dependable Contract Manufacturing

National Leader in Aluminum Busbar Production

Innovations in Aluminum Busbar Technology

Why Choose Aluminum Over Copper?

Quality Assurance & Certifications

Proudly Made in the USA

Serving Diverse Industries

The AP Precision Advantage