Essential Guide to Custom Metalwork Planning for Your Next Project

Key Takeaways

- Grasping Customized Metalwork Strategy

- Components of an Effective Tailored Metal Initiative

- Categories of Personalized Metal Items

- Tailored Metal Creation Methods

- Optimal Approaches for Customized Metalwork Strategy

- Obstacles in Tailored Metal Project Oversight

Understanding Custom Metalwork Planning

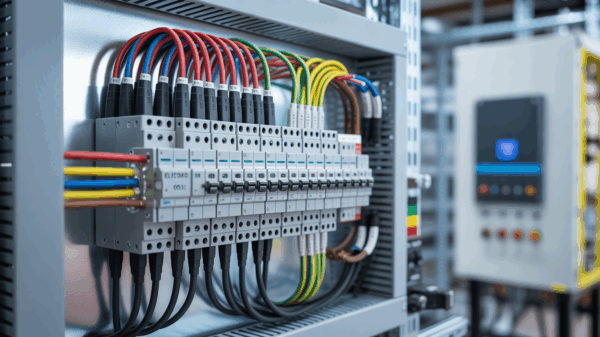

Custom metalwork planning is crucial for ensuring the success of any metal project, whether it involves sheet metal, white metal, or other materials. A well-structured plan helps streamline the manufacturing process and minimizes the risk of costly rework. Key factors in custom metalwork planning include the selection of appropriate fabrication techniques such as CNC machining, milling, and metal stamping, which all play vital roles in achieving desired specifications. The effective use of welding machines enhances the durability of the final product. By considering these elements, designers and engineers can create efficient workflows that optimize both the design and the execution of metal fabrication projects.

Importance of Custom Metalwork Planning

Effective custom metalwork planning serves as a critical foundation for successful projects. It involves developing detailed designs that consider various factors such as the type of metals used, including stainless steel and other durable materials. By carefully planning the project, designers can ensure the appropriate selection of metal sheets for specific applications. This proactive approach minimizes risks associated with the fabrication process, paving the way for precision in welding techniques like TIG welding and metal inert gas welding.

The impact of custom metalwork planning extends beyond aesthetics and function. Strategic planning influences the entire fabrication process, ensuring that each stage is executed seamlessly within the factory environment. By understanding the capabilities of different fabrication processes, including cutting and bending, teams can optimize their workflow and achieve high-quality results. Such thorough planning not only enhances the efficiency of the project but also elevates the overall craftsmanship of the final steel structures.

| Planning Factor | Description | Impact on Project |

|---|---|---|

| Metal Selection | Choosing appropriate metals like stainless steel for durability | Ensures the final product meets strength and longevity requirements |

| Welding Techniques | Implementation of TIG and MIG welding methods | Enhances precision and strength of metal joints |

| Fabrication Processes | Understanding cutting, bending, and other processes | Optimizes workflow and improves overall quality of workmanship |

| Project Workflow | Developing a streamlined sequence of operations | Reduces downtime and increases efficiency throughout the project |

Key Steps in the Planning Process

Effective custom metalwork planning begins with a clear understanding of the project specifications. This involves determining the desired outcome and selecting appropriate cutting tools, materials, and techniques. Fabricators should consider various welding methods, such as MIG, TIG, stick welding, spot welding, and gas welding, to achieve the required strength and finish. Computer-aided designs (CAD) play a crucial role in visualizing the project and ensuring accuracy in dimensions. Material selection should align with the project’s goals and budget while maintaining quality and durability.

Following the initial planning phase, it’s vital to maintain an organized inventory of tools and materials. This inventory aids in tracking the resources necessary for the project, ensuring that fabricators have everything they need for successful execution. Incorporating grinding and finishing techniques will enhance the final product’s appearance and functionality. Careful planning at each step not only streamlines the fabrication process but also supports collaboration with manufacturers to ensure timelines and quality standards are met.

Elements of a Successful Custom Metal Project

Successful custom metal projects require meticulous custom metalwork planning to ensure that every element aligns with the project’s objectives. Selecting materials like carbon steel presents both opportunities and challenges, particularly with respect to supply chain issues that can disrupt timelines. Advanced tools such as computer-aided design (CAD) enable precise modeling of components, crucial for industries like aircraft manufacturing where tolerances are tight. Fabricators must account for processes like polishing to enhance both aesthetic and functional aspects while considering prevention against rusting. Integrating enterprise resource planning systems can streamline the entire workflow, ensuring all aspects from production to delivery are synchronized, thereby mitigating the risks associated with supply chain disruptions and enhancing overall project success.

Defining Project Objectives

Establishing clear project objectives is crucial in custom metalwork planning. These goals guide the direction of the project and help define what successful custom metal pieces look like. Whether the aim is to create large custom metal structures or more intricate custom metal products, having well-defined objectives ensures that every phase of custom metal fabrication aligns with the desired outcomes. Clients should articulate their metal work needs and expectations at the outset to enable custom metal solutions that fulfill their vision.

A thorough understanding of project objectives leads to more efficient decision-making throughout the project lifecycle. By identifying the specific requirements for custom metal work, project managers can better allocate resources and streamline production processes. This clarity helps in selecting the right techniques for custom metal fabrication, which ultimately contributes to the successful execution of the project. Defining these objectives early allows teams to anticipate challenges and adapt to changes effectively, ensuring that the next custom metal endeavor is both timely and within budget.

| Project Objective | Description | Key Metrics | Deadline |

|---|---|---|---|

| Define Metal Specifications | Specify types, grades, and finishes of metals to be used. | Compliance with standards, client approval | End of Week 1 |

| Design Approval | Obtain client sign-off on design drafts and renderings. | Client feedback, revision counts | End of Week 2 |

| Production Timeline | Establish a timeline for fabrication and delivery. | Adherence to schedule, production milestones | End of Week 4 |

| Budget Management | Keep project costs within the defined budget limits. | Cost tracking, budget variance | Ongoing |

Budget Considerations for Custom Metal Projects

Effective custom metalwork planning begins with a clear understanding of budget constraints. Allocating sufficient funds for both materials and labor ensures that metal fabrication projects maintain a high standard of quality. Collaborating with reputable custom metal fabricators provides insight into potential costs. These professionals can offer guidance on specific metal fabrication techniques that may affect the overall budget. Full-service custom metal shops often present various options, from polished metal products to oversized custom metal elements, allowing for more informed financial decisions.

A well-outlined budget should consider the scope of the project and the specific needs of the client. Identifying the types of custom sheet metal required and the complexity of the designs will help in estimating costs accurately. Engaging with a skilled custom metal fabricator can reveal additional expenses related to specialized equipment or finishing processes. Ultimately, thoughtful budget considerations contribute to the success of metal fabrication projects, as they enable precise planning and execution while adhering to client expectations.

Types of Custom Metal Pieces

Custom metalwork planning plays a crucial role in the metal fabrication industry, particularly when it comes to creating diverse types of custom metal pieces. From decorative elements to functional applications, the choices are vast. Each piece involved in a steel fabrication project reflects careful consideration of the metal components utilized. A leading metal fabrication company can transform standard metal fabrication practices into custom metal masterpieces. By focusing on the metal cutting and overall metal fabrication process, clients can ensure that their unique metal components meet specific requirements. Thoughtful planning and execution are essential for the success of the entire metal fabrication effort, resulting in high-quality metal products that stand out in functionality and aesthetics.

Decorative Custom Metal Work

Custom metalwork planning plays a crucial role in creating decorative elements that enhance aesthetics and functionality. By collaborating with skilled metal fabrication companies, clients can access top-quality metal fabrication tailored to their unique designs. Large metal fabrication projects often require intricate detailing and the incorporation of durable metal components. Understanding shop capabilities and available materials ensures that the end product meets the vision and expectations of the client.

The custom fabrication process for decorative metal work involves careful consideration of design and costs. Non-standard metal parts may be necessary to achieve specific artistic effects. By thoroughly planning the project, clients can ensure that every piece is precisely fabricated to align with their overall vision. This level of attention to detail ultimately results in stunning, high-quality fabricated metal products that stand the test of time.

Functional Custom Metal Applications

Functional custom metal applications encompass a wide range of industries and needs. Effective custom metalwork planning is crucial to ensure each fabricated metal structure meets specific design requirements. Many custom fabrication processes focus on creating metal pieces that serve practical purposes, such as structural support or machinery components. Southern metal fabricators often excel in delivering high-quality, durable metal parts tailored to the unique demands of each project design.

Project planning plays a vital role in the success of functional metal structures. Engaging with experienced professionals can enhance the outcome, especially when intricate welding tasks are involved. Identifying the right metal for each application not only optimizes functionality but also ensures longevity. Custom design allows for greater flexibility, enabling a seamless integration of fabricated metal structures into various environments, whether for industrial or commercial use.

Custom Metal Fabrication Techniques

Effective custom metalwork planning is essential for achieving successful outcomes in various fabrication projects. Fabrication techniques must be tailored to meet unique design requirements, particularly for complex manufacturing projects that involve intricate designs. Trusted metal fabrication specialists utilize innovative planning to transform raw materials into shaped metal components that align with specific design specifications. Whether creating custom fabrication products or crafting bespoke metal sculptures, accurate metal components are crucial for ensuring the integrity and functionality of the final piece. By implementing proper techniques for cutting metal pieces, professionals can achieve greater precision in delivering specialized designs that resonate with the client’s vision.

- Ensure that raw materials are chosen based on the project’s specific requirements.

- Utilize advanced cutting techniques such as laser cutting or water jet cutting for high precision.

- Employ welding techniques that best suit the types of metals used and the intended application.

- Consider using CNC machining for detailed designs and complex shapes.

- Implement quality control measures throughout the fabrication process to maintain standards.

- Collaborate closely with clients to refine designs and ensure all specifications are met.

- Stay updated on the latest technologies and methods in metal fabrication to enhance efficiency.

Common Fabrication Methods

Custom metalwork planning involves selecting the appropriate fabrication techniques to match unique design specifications. Different methods exist, such as precision sheet metal fabrication and manual machining, which cater to various product designs. Engaging with a fabrication facility that utilizes state-of-the-art manufacturing equipment can significantly enhance the outcome of your project. Careful planning ensures the selected fabrication technique aligns with your project’s requirements and objectives.

Each fabrication technique requires detailed planning to ensure efficiency and quality. For instance, precision sheet metal techniques often demand a focus on the specific properties of the used metals, affecting the final product’s durability and appearance. To achieve the best results, businesses should contact P&D Metal Works with your location and area of interest. This collaborative effort streamlines the design process and ensures that all facets of custom metalwork planning are meticulously addressed.

Choosing the Right Process for Your Project

The selection of appropriate methods during the custom metalwork planning phase is crucial for achieving desired outcomes in fabrication projects. Understanding the various welding processes is essential to ensure that the selected technique aligns with the specifications of the custom-made parts. Good planning during the initial stages allows for better coordination with the fabrication shop, helping craftsmen choose suitable raw metal pieces that fit the project’s requirements effectively.

Evaluating options for contract manufacturing at the planning stage can lead to better resource utilization and time management. This evaluation process involves assessing the capabilities of various fabrication shops and understanding their expertise in producing exceptional sheet metal and custom parts. Effective place planning ensures that all necessary factors are considered before finalizing the fabrication method, leading to smoother operations and high-quality results in custom metalwork planning.

Best Practices for Custom Metalwork Planning

Effective custom metalwork planning is essential for achieving successful outcomes in any project. Engaging talented craftsmen early in the design stage ensures that intricate designs are translated into durable products. Stainless steel offers excellent durability, making it a preferred choice for many custom metal applications. Addressing project requirements at the outset allows teams to shape metal appropriately and select suitable raw metal materials. Implementing a certified welding procedure in alignment with applicable welding codes is crucial for ensuring structural integrity. Prioritizing quality fabrication work enables the production of custom products that meet or exceed industry standards, ultimately leading to a successful realization of the envisioned fabrication product.

Collaborating with Designers and Engineers

Effective collaboration with designers and engineers is crucial for successful custom metalwork planning. These professionals help translate a complete design concept into tangible parts. Their expertise ensures that the design aligns with specific project needs. Many fabrication shops rely on designers to create detailed shop drawings design that guide the production process. With a focus on quality manufacturing, the use of specialized tools and modern fabrication techniques allows for precision in producing tailored parts from different metals.

The initial planning process benefits greatly from input from both designers and engineers. This relationship ensures that the craftsmanship meets the project’s requirements while adhering to industry standards. A full-service fabrication shop can offer insights on the best materials and methods to achieve desired outcomes. Engaging these experts early in custom metalwork planning can streamline workflows and enhance the final product’s overall quality. Their collaborative efforts lay the foundation for successful project execution.

Tips for Ensuring Quality and Precision

A thorough approach to custom metalwork planning is essential for achieving high-quality craftsmanship results. Engaging with designers early in the process ensures that the detailed design concept harmonizes with both aesthetic and functional design requirements. Utilizing CAD design can help visualize the one-off design, allowing for adjustments before moving to the fabrication stage. Collaborating with fabrication specialists skilled in using appropriate materials is crucial for executing the vision accurately.

Focusing on quality during custom metalwork planning can significantly enhance the final product. It’s important to establish stringent quality control measures throughout the fabrication process. Regular checkpoints with skilled craftsmen can help maintain precision in the dimensions and finishes. Attention to detail in the selection of materials and fabrication methods plays a pivotal role in the success of custom projects, yielding durable and visually appealing fabrications.

Challenges in Custom Metal Project Management

Effective custom metalwork planning is essential to navigate various challenges that arise during project management. Each new project requires adherence to specific required specifications, which may vary significantly, especially for applications like metal roofing or intricate designs involving metal surfaces. Failure to meet these specifications often leads to costly rework, undermining both timelines and budgets. Projects involving axis fabrication and specialized equipment demand close attention to detail, as precision fabrication plays a critical role in achieving desired outcomes. Ensuring clear communication and understanding between all stakeholders can aid in minimizing these challenges, making future projects more efficient.

- Ensuring clear specifications to avoid misunderstandings

- Implementing effective project tracking systems

- Regularly conducting quality checks throughout the fabrication process

- Maintaining open lines of communication among team members and clients

- Anticipating potential delays due to material availability

- Investing in skilled personnel to enhance craftsmanship and precision

- Developing contingency plans for unexpected challenges and changes

Conclusion

Effective custom metalwork planning is essential for the success of any project involving metal. Proper planning ensures that metal fabrication processes such as sheet metal work, CNC machining, and steel fabrication are conducted efficiently. Utilizing advanced techniques like metal stamping and precision milling, along with reliable welding machines, can significantly enhance the quality of the final product. Identifying potential challenges early enables teams to address issues related to rework or manufacturing delays proactively. Through meticulous custom metalwork planning, projects can achieve the desired balance between aesthetics and functionality, ultimately leading to successful outcomes.

FAQS

How can I effectively plan my next project involving custom metal components and ensure successful metal fabrication?

Effective planning for your next project involves understanding the capabilities of your metal fabrication shop, including the skilled craftsmanship available and the types of different metal components they work with. It’s essential to discuss design, planning, and materials with the shop, considering the costs associated with cutting metal pieces. To start the process, contact P&D Metal Works with your business information, location, and your area of interest regarding fabrication services and industrial equipment. This will help ensure a successful outcome for your project in custom metal.

How can I ensure successful metal fabrication for my next metal fabrication project involving custom metal components, taking into account design, costs, and materials?

To ensure successful metal fabrication for your next project involving custom metal, it’s essential to focus on the design, costs, and materials. Start by clearly defining your project requirements and shop capabilities. When planning, consider how you will cut metal pieces effectively and the materials that best suit your needs. For tailored metal fabrication offers, contact P&D Metal Works with your business information, including your location and your area of interest. This approach will help streamline the planning process and set your project up for success.

What steps should I follow for effective project planning in custom metalwork to ensure that the next metal fabrication aligns with the design, shop capabilities, costs, and materials needed?

Effective project planning in custom metalwork ensures that your next metal fabrication is successful. Start by clearly defining the project objectives and scope. Identify the specific custom metal components required and gather information on the design, shop capabilities, costs, and materials. It’s advisable to contact P&D Metal Works with your business information, location, and your area of interest to get personalized assistance and ensure all factors are considered during the planning phase.

What considerations should I keep in mind for successful project planning in custom metalwork to ensure effective metal fabrication while managing design, shop capabilities, costs, and materials?

To ensure that your project involving custom metal fabrication is successful, you should prioritize thorough planning. This involves clarifying your design, evaluating the shop capabilities, and accurately estimating costs and materials. Additionally, it’s beneficial to contact P&D Metal Works with your business information, location, and your area of interest to receive tailored guidance for your custom metal project.

What tips can help streamline the project for custom metal fabrication, ensuring it aligns with design, shop capabilities, costs, and materials?

To streamline your project for custom metal fabrication, it’s essential to start with thorough planning. Begin by defining your design requirements clearly. Understanding your shop capabilities will help set realistic expectations, while careful budgeting will prevent overspending on costs. Ensure you have a detailed list of materials needed for the project. For tailored advice, consider contacting P&D Metal Works with your business information, location, and your area of interest, as they can guide you through the process to ensure successful metal fabrication.

What strategies can I implement to improve the planning of a project involving custom metal components and ensure that the metal fabrication meets the necessary design requirements, taking into account shop capabilities, costs, and materials?

To improve the planning of your project involving custom metal components, it’s essential to establish a clear design outline that aligns with the capabilities of your selected shop. Furthermore, evaluating costs and materials in advance will ensure that your metal fabrication meets budgetary constraints. By thoroughly researching and planning these aspects, your project custom metal fabrication ensures a smoother execution. For tailored support, contact P&D Metal Works with your business information, location, and your area of interest.

What are some key elements to consider in the planning phase of a custom metalwork project to achieve effective metal fabrication that meets design requirements while considering shop capabilities, costs, and materials?

When planning a custom metalwork project, it is essential to focus on key elements such as design, shop capabilities, costs, and materials. Ensuring proper communication with your metalwork partner can help align these elements effectively. For professional assistance, contact P&D Metal Works with your business information, location, and your area of interest to facilitate the planning process.

What information should I provide when I want to contact P&D Metal Works for a custom metalwork project to discuss planning, design, shop capabilities, costs, and materials?

When contacting P&D Metal Works for your custom metalwork project, it’s essential to include your business information, location, and your area of interest. This will help us better understand your needs regarding planning, design, shop capabilities, costs, and materials, enabling us to assist you effectively.

How can I optimize my custom metalwork planning process to ensure that it addresses the necessary design, shop capabilities, costs, and materials effectively?

To optimize your custom metalwork planning process, focus on thorough initial research and development. Ensure clarity in the design specifications, assess the shop capabilities available to you, and prepare a comprehensive budget that outlines all costs related to your project. Additionally, gather precise information about the materials you intend to use. If you need assistance, remember to contact P&D Metal Works with your business information, location, and your area of interest for tailored support.

What information should I include when contacting P&D Metal Works regarding my custom metalwork project to effectively discuss design, shop capabilities, costs, planning, and materials?

When contacting P&D Metal Works, you should provide your business information, location, and your area of interest, as this will help facilitate a discussion about the key aspects of your custom metalwork project, including design, shop capabilities, costs, planning, and materials.