Your Comprehensive Winter Drilling Conditions Guide for Cold Weather Drilling

Key Takeaways

- Overview of cold season drilling circumstances and their implications

- Readiness steps for conducting operations during the winter

- Methods for efficient drilling in frigid conditions

- Recommended strategies for achieving successful winter drilling

- Ecological factors to consider during cold season drilling

- Typical obstacles faced in winter drilling activities

Winter Drilling Conditions Guide | Understanding Winter Drilling Conditions

Understanding winter drilling conditions is crucial for achieving optimal performance in cold environments. The winter drilling conditions guide emphasizes the impact of temperature on drilling efficiency, which can greatly affect the operation of drilling rigs and machines. Cold weather can alter the properties of drilling fluids, making it essential for drillers to select appropriate drilling fluids that ensure consistency and prevent freezing. Techniques such as horizontal directional drilling may require adjustments to standard practices, while maintaining the integrity of the drill rig and drilling equipment becomes paramount. A proactive approach in assessing ground stability and understanding the nuances of winter conditions will enable drillers to adapt effectively and mitigate potential challenges.

Winter Drilling Conditions Guide | Impact of Temperature on Drilling Efficiency

Drillers must be aware that winter storms can significantly impact drilling efficiency. Plummeting temperatures can lead to the formation of ice, which poses challenges for both the equipment and the crew. The effectiveness of drill bits is often diminished in extreme cold, and the behavior of drill strings can be unpredictable as they encounter frozen conditions. Operators may need to utilize ice scrapers to maintain clean surfaces and ensure proper function. Time lost due to snow days or snowstorms must also be factored into project planning, reflecting the importance of a comprehensive winter drilling conditions guide.

Cold weather not only affects drilling operations but also influences the nature of drill cuttings produced. In freezing temperatures, materials can become more brittle, complicating the process of managing and removing drill cuttings from the site. Drillers may find that adjusting techniques is essential for maintaining productivity during harsh winter drilling conditions. Proper equipment maintenance, including the inspection of drill strings, is vital to mitigate risks posed by ice and other environmental factors. Adhering to a detailed winter drilling conditions guide ensures that teams remain prepared to tackle the challenges presented by frigid weather.

Assessing Ground Stability in Cold Weather

Understanding ground stability during winter drilling is crucial for safe and efficient operations. The effects of snowfall and extreme weather conditions can significantly impact the firmness of the ground. Variations in operating temperatures may lead to changes in soil composition, making it essential for drilling teams to regularly assess the stability of the terrain. Proper evaluation helps in selecting the appropriate drill bits and pipe configurations that can withstand icy conditions, ensuring that the hydraulic system performs optimally.

Cold weather can also cause hydraulic oil to thicken, impacting the performance of hydraulics in drilling equipment. Monitoring the hydraulic system is vital for maintaining functionality under challenging work conditions. Failure to account for ground stability and hydraulic performance in winter drilling conditions can lead to operational delays and increased costs. By closely following a winter drilling conditions guide, teams can mitigate risks and prepare for the unique challenges posed by frozen environments.

- Monitor soil temperature regularly to detect changes in stability.

- Use appropriate snow removal techniques to maintain access to drilling sites.

- Select drill bits designed for cold weather operations to enhance effectiveness.

- Regularly check hydraulic oil viscosity and switch to winter-grade oil if needed.

- Implement pre-drill inspections to identify potential ground instability issues.

- Train personnel on the unique challenges of winter drilling environments.

- Maintain constant communication within the team to address any operational concerns promptly.

Preparing for Winter Drilling Operations

Effective preparation for winter drilling operations involves understanding the winter drilling conditions guide to ensure optimal performance in cold environments. Hydraulic systems must be regularly checked, as low temperatures can affect hydraulic oils, potentially leading to malfunctions. Equipment like drills should be equipped with ice cleats for better traction on icy surfaces, while tools such as steel shovels are essential for clearing any snow or ice buildup from work areas. Awareness of how extreme temperatures impact materials and equipment is crucial for avoiding breakdowns and ensuring safety. For plumbers and other field professionals, adhering to these guidelines will facilitate smoother drilling operations despite the challenges posed by winter.

| Preparation Aspect | Recommended Actions | Importance |

|---|---|---|

| Hydraulic System Maintenance | Regular checks on hydraulic oils | Prevents malfunctions in cold temperatures |

| Equipment Modification | Equip drills with ice cleats | Enhances traction on icy surfaces |

| Tool Availability | Keep steel shovels on hand | Essential for clearing snow and ice |

| Material Awareness | Understand material performance in low temps | Avoids breakdowns and ensures safety |

Essential Gear and Equipment for Winter Drilling

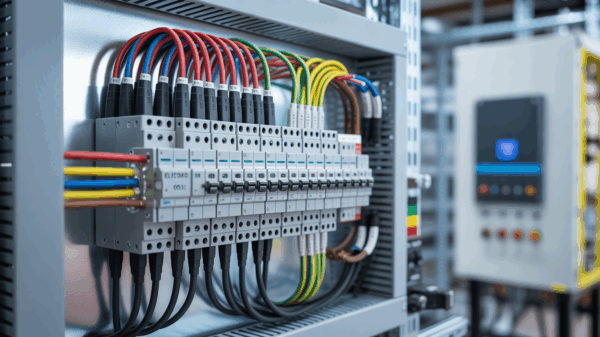

Proper gear and equipment are critical for ensuring safety and efficiency during winter drilling operations. Following a winter drilling conditions guide, operators must select the right drilling tools designed to withstand low temperatures. Standard operating procedures should include specifications on plumbing and heating elements to prevent freezing. Utilizing high-quality drilling equipment can enhance the drilling process, promoting optimal performance even in challenging winter drilling conditions.

Planning ahead is essential for a successful drilling project during the winter season. Every team should ensure that all drilling equipment is inspected, maintained, and appropriately winterized. This includes checking the integrity of hydraulic systems and ensuring that fuel sources are dependable despite frigid temperatures. Adhering to the winter drilling conditions guide helps teams navigate the complexities of environmental drilling while reducing downtime and maintaining productivity throughout the drilling season.

Safety Protocols for Winter Work Environments

Establishing clear safety protocols is crucial for successful drilling projects in winter drilling conditions. Drilling companies must ensure that all personnel are trained on the unique challenges posed by cold weather at various drilling sites. Protective gear should be standard, and all team members should understand the procedures for working in freezing temperatures. Keeping equipment, such as directional drilling machines, warm and well-maintained is essential to prevent malfunctions that could jeopardize the drilling operation.

Regular safety meetings and check-ins can help address any concerns that arise during winter drilling operations. Drilling equipment performs optimally when operators adhere to safety protocols tailored for winter conditions. A focused winter drilling conditions guide should outline how to monitor and maintain the environment around drilling sites, ensuring that the impact on local ecosystems is minimized. By prioritizing safety, drilling companies can meet their directional drilling needs while successfully conducting environmental drilling projects in challenging weather.

Techniques for Effective Winter Drilling

Navigating extreme winter conditions requires a thorough understanding of the winter drilling conditions guide to ensure top-quality foundation drilling. Using the right winter equipment is essential to prevent issues such as drilling fluid freezing, which can disrupt operations. Environmental drilling sites often demand specific adaptations in techniques to maintain efficiency. Adjusting drilling parameters, such as the type of water-based drilling fluid, can enhance performance in cold weather. An environmental drilling company must consider the unique challenges posed by winter conditions to execute high-impact drilling while adhering to best practices. Proper planning and knowledge of foundation drilling equipment are crucial to overcome the obstacles presented in winter operations.

- Select the appropriate drilling fluids that remain effective at low temperatures.

- Utilize insulated drilling equipment to prevent freezing and maintain operational efficiency.

- Schedule operations during the warmest parts of the day to reduce cold-related disruptions.

- Regularly monitor weather conditions to adapt drilling strategies accordingly.

- Implement safety measures to protect personnel from extreme cold and frozen surfaces.

- Maintain clear communication with all team members to ensure coordinated efforts in challenging conditions.

- Invest in training for staff to handle winter-specific challenges in drilling operations.

Choosing the Right Drilling Method for Cold Conditions

Selecting the appropriate drilling method is crucial under winter drilling conditions. The specific challenges posed by severe winter weather necessitate careful consideration of drill equipment and techniques. Drill crews should prioritize options that enhance efficiency while managing the effects of freezing temperatures. Techniques that utilize heated drill water can maintain fluidity and prevent icing in lines. As winter storm preparations become essential, strategies must be in place to ensure drill rigs and drill trucks remain operational at the drill site.

Drillers must also assess the suitability of various winter approaches for their winter projects. Adjusting drilling parameters in accordance with cold conditions can significantly impact outcomes. Techniques like rotary drilling or using specialized bits designed for frozen soil can enhance penetration rates. Emergency winter conditions may arise unexpectedly, making it vital for teams to remain adaptable and ready to implement alternative drilling strategies laid out in the winter drilling conditions guide. Planning for the unexpected allows crews to mitigate risks and maintain progress throughout the winter season.

Adjusting Drilling Parameters for Winter Environments

Extreme winter temperatures can significantly affect drilling performance, requiring adjustments to drilling parameters. Many drillers must consider the properties of liquid drilling fluids, which can thicken or freeze under icy storm conditions. Utilizing specialized drill rigs designed to handle such challenges becomes essential. A winter drilling conditions guide emphasizes the importance of ensuring that the drill rig pokes through the frozen ground efficiently while maintaining a full drill rate.

Maintaining optimal drilling parameters is crucial for successful operations during dangerous winter storms. Effective scheduling around potential weather disruptions can minimize downtime at the drill station. As drill manufacturers continue to innovate, they provide equipment options that enhance the adaptability of drilling systems. Understanding how to adjust parameters not only improves efficiency but also increases safety for crews working in challenging environments associated with winter drilling conditions.

Best Practices for Winter Drilling Success

Effective management of winter drilling operations requires adherence to best practices that ensure efficiency and safety. A comprehensive winter drilling conditions guide is essential for understanding how factors like icy terrain and snow-covered environments affect the drilling process. Utilizing arctic grade tools can significantly enhance performance under harsh conditions, while specialized drill support trucks are necessary for transporting equipment and personnel across icy ground. Employing drilling fluid additives helps maintain optimal flow and consistency, even in frigid temperatures. Cold weather preparedness is critical, with drill shacks providing a safe environment for crews and allowing for essential breaks during long operations. Prioritizing cold weather safety measures can prevent breakdowns and ensure that drillers remain productive in cold climate operations. With careful planning and the right gear, companies can navigate the challenges of winter drilling successfully.

Maintaining Equipment Performance in Cold Weather

Cold weather significantly impacts drilling operations, making it crucial to adhere to a winter drilling conditions guide for optimal equipment performance. During the winter months, icy conditions can cause complications that affect machinery. Operators must utilize arctic grade equipment designed to withstand severe temperatures and harsh environments. Ensuring that drill rods and driller hoses are appropriate for cold weather jobsites prevents failures that could lead to costly delays. Proper maintenance and regular inspections of drill cabs are vital to ensure they perform efficiently throughout the winter.

Wearing winter gloves is essential for drillers working in frigid conditions. Keeping hands warm and nimble enhances safety and performance during operations. Implementing a routine of checking equipment against arctic grade specifications will promote reliability when cold weather strikes. Operators should also consider storing equipment in heated areas to prevent freezing and ensure that all machinery is ready to perform once winter hits. Following these guidelines can greatly improve efficiency and safety in snowy drilling environments.

Scheduling and Planning for Winter Operations

Winter drilling operations require meticulous scheduling and planning to ensure efficiency and safety. The winter drilling conditions guide emphasizes the importance of accounting for cold weather impacts, such as frozen ground conditions and the potential for unexpected winter storms. Workers need to winterize their equipment, including skids and frozen condition equipment, before the drilling season begins. Overall rig inspections should be prioritized to mitigate risks associated with arctic grade conditions, ensuring that everything is operational from the first free drill shots.

Proper planning also involves adjusting timelines to accommodate weather fluctuations, particularly during major snowstorms which can delay operations. Establishing a contingency plan allows teams to respond effectively to any unexpected winter storm. Keeping communication channels open among crew members ensures that everyone is informed about cold weather conditions, allowing for a smoother operation despite the challenges that winter may present. This comprehensive approach is crucial in following the winter drilling conditions guide successfully while maintaining productivity and safety throughout the drilling process.

| Task | Description | Timeline | Responsible Team |

|---|---|---|---|

| Equipment Winterization | Prepare and winterize all drilling equipment to withstand cold temperatures. | 2 weeks before drilling | Maintenance Team |

| Site Inspections | Conduct thorough inspections of the rig and site to identify any potential issues. | 1 week before drilling | Safety Team |

| Weather Monitoring | Establish a system to monitor and report weather conditions continuously. | Ongoing | Operations Team |

| Contingency Planning | Create and communicate plans to handle unexpected delays due to weather. | 1 month before drilling | Management Team |

Environmental Considerations for Winter Drilling

Proper planning for winter drilling operations requires an awareness of various environmental factors that can significantly impact both the process and surrounding ecosystems. The winter drilling conditions guide emphasizes the need to monitor ice buildup, which can obstruct access to drilling sites and lead to safety hazards. Icy air and colder weather conditions can affect equipment performance, potentially causing frozen water lines that disrupt operations. Winter storage of materials becomes crucial to prevent deterioration and ensure accessibility during harsh weather conditions. Workers must be equipped with proper winter PPE, including cut-resistant winter gloves, to protect themselves while drilling deep holes in cold climates. Understanding these considerations is vital for maintaining compliance with regulations while minimizing the impact on the environment during extreme weather conditions.

Minimizing Impact on Surrounding Ecosystems

The winter drilling conditions guide emphasizes the importance of considering ecological impacts during cold weather operations. Snowfall events and heavy snowfall can create barriers to access and increase the risk of disturbing local wildlife habitats. During extreme cold, operators must be cautious of the frozen ground and the potential for frozen mud pumps that can hinder efficiency. Working in a chilly setting demands careful planning to minimize disruption caused by icy roads and challenging outdoor temperatures.

Adopting best practices outlined in the winter drilling conditions guide can significantly reduce environmental footprints. Implementing measures to protect against erosion, especially in open trench areas, is crucial in colder climates where ground stability may be compromised. Operators should aim for optimal operating temperatures to maintain equipment efficiency while ensuring that their activities do not adversely affect the surrounding ecosystems. Integrating sensitive site assessments can facilitate responsible drilling operations even in the harshest winter conditions.

Regulations and Compliance During Winter Drilling

Understanding regulations and compliance during winter drilling is crucial for ensuring safe operations under challenging conditions. The winter drilling conditions guide emphasizes the importance of utilizing arctic-grade materials to combat issues like rig breakdowns, which can occur due to hydraulic failures or the use of inadequate winter-grade lubricants. Cold temperatures and the presence of 4-ft snowbanks can severely affect drilling efficiency, making it vital to adhere to established standards to mitigate risks in the coldest weather.

Compliance also involves understanding the environmental regulations that govern drilling activities in fragile ecosystems. Operators must be equipped with specialized drill bits designed to perform optimally in winter drilling conditions, minimizing disturbance to the surroundings. Western equipment solutions provide essential tools and technology to ensure adherence to regulations during the winter season, promoting operational safety while navigating the unique challenges presented by winter freezes.

Common Challenges in Winter Drilling

Cold weather presents significant challenges in winter drilling conditions guide, particularly in colder regions where extreme temperatures can hinder operations. Medium-sized drills require careful attention as the cold brings difficulties such as frozen lines and a cold system that can impede progress. Maintaining the flow of hydraulic fluids warm enough to function effectively is crucial for the rig to operate smoothly. Drillers often find that holes take longer to create due to the soil’s increased density in frozen conditions. Adapting to these challenges is essential for successful operations throughout the colder months, where proper planning and equipment management can mitigate the adverse effects of an extreme climate.

Conclusion

Understanding the nuances outlined in a winter drilling conditions guide is essential for successful operations in cold environments. Ice falls and slippery surfaces present unique challenges that can significantly hinder construction progress. The frozen earth and freezing zones complicate drilling efforts, necessitating comprehensive preparation and adaptability. As companies strive to maintain efficiency during winter months, adapting techniques from warm weather months can provide valuable insights. A strong focus on safety, equipment maintenance, and strategic planning is crucial to navigating the difficulties of winter drilling conditions, ensuring projects remain on track despite harsh weather challenges.

FAQS

What are the best practices for using hydraulic hoses in cold weather environments during directional drilling services?

In cold weather environments, it’s crucial to ensure that hydraulic hoses are rated for cold weather use to prevent breakdowns. When operating a drilling machine warm, consider the impact of snow-cover environment on the drilling fluids industry as well. Utilizing go-drill techniques can enhance efficiency in such conditions, ensuring that breakdown drillers can effectively manage the challenges posed by harsh winter conditions.

How do winter drilling conditions affect directional drilling services overall?

Winter drilling conditions can significantly impact directional drilling services due to challenges such as low temperatures, frozen ground, and ice. Proper planning and adaptation to these conditions are crucial to ensure the success of directional drilling service operations, including using specialized equipment and techniques tailored for cold weather.

What specific challenges do directional drilling services face during extreme winter drilling conditions?

During extreme winter drilling conditions, directional drilling services encounter several challenges such as increased friction on drill bits due to colder temperatures, potential freezing of drilling fluids, and difficulties with equipment performance. It’s essential to implement strategies that mitigate these issues to ensure efficient operation and avoid delays.

What safety measures should be taken during directional drilling services under severe winter drilling conditions?

When conducting directional drilling services in severe winter conditions, it’s crucial to implement safety measures such as ensuring equipment is winterized, providing proper training for the crew on handling cold weather hazards, and conducting regular inspections of machinery to prevent failures due to freezing temperatures. Additionally, keeping an adequate supply of de-icing materials on hand is essential to maintain safe working conditions.

What preparations should teams make for successful directional drilling services in winter drilling conditions?

To ensure successful directional drilling services during winter drilling conditions, teams should conduct thorough equipment inspections, ensure proper insulation for hoses and cables, and prepare for potential changes in soil conditions. Implementing a detailed weather monitoring plan and training crew members on cold weather operations will also enhance safety and efficiency in winter drilling conditions.